Estimated reading time: 3 minutes

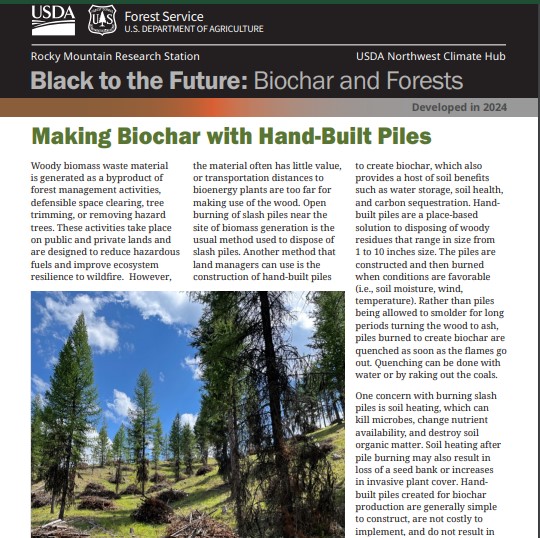

Fuels management activities, carried out on both public and private lands, aim to reduce fuels and strengthen ecosystem resilience to wildfires. These activities can include clearing vegetation for defensible space around infrastructure, trimming trees and brush, and removing hazard trees. Each of these activities creates woody biomass waste – the woody material that is cut or removed from trees and brush. Because the woody biomass that is removed is often small or in poor condition, it can have little economic value. Even where woody biomass waste has potential value as a source of bioenergy, the transportation costs to distant bioenergy plants often outweigh the economic benefits.

Currently, land managers typically dispose of this woody biomass waste in piles (known as slash piles) that are burned. But burning slash piles can cause soil heating, which can kill beneficial microbes, alter nutrient availability, and destroy soil organic matter. It can also lead to the loss of seeds stored in the soil (known as the seed bank) and encourage the growth of invasive plants.

However, land managers have an alternative method they can consider: using hand-built piles to create biochar. Biochar is a charcoal-like substance made by burning organic material from forest and agricultural biomass in a controlled process. When applied to soil, biochar offers several advantages, including improved water retention, increased soil health and microbial activity, and improved carbon storage. Hand-built piles for biochar production also offer a localized solution for disposing of woody debris between 1 and 10 inches in size. While traditional slash piles burn at high temperatures that can damage the soil underneath the piles, piles built for biochar production are constructed in such a way as to reduce the heat intensity, reduce smoke and greenhouse gas emissions, store valuable carbon, and benefit the soil.

Hand-built piles for biochar production are generally simple and inexpensive to construct. However, building biochar piles might require land managers to learn a new approach compared to their usual methods of constructing and burning slash piles.

Pile-building tips to maximize biochar production

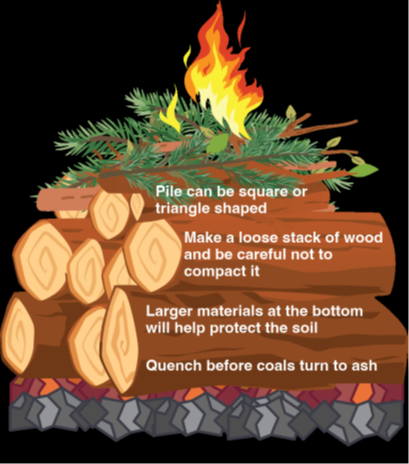

Hand-built piles tailored to biochar production look different than traditional slash piles. Here are some tips to improve biochar production from hand-built piles:

- Make a loose stack of wood by placing one piece of wood at a time. Avoid compacting piles to ensure adequate airflow.

- The pile does not need to be elevated above the ground. Piles can rest on a few supporting branches or logs.

- Piles can be square- or triangle-shaped.

- If piles will be burned in the winter, cover them until they are lit to avoid moisture absorption.

- Light the pile from the top.

- Quench (or rake out coals) before coals turn to ash.

- Larger material at the bottom of the pile will help to protect the soil, while lighting the top of the piles develops a “flame cap.” This technique contains the combustion, which helps the wood burn more efficiently and creates less smoke.

- Once the flames go out, the coals should be raked out across the soil or quenched with water to conserve as much charcoal as possible.

Benefits and challenges of using hand piles to create biochar

As with many practices that can help address waste materials or environmental concerns, producing biochar and using it as a soil amendment has both benefits and challenges, which are important to consider when deciding whether to use hand-built piles to produce biochar as a woody biomass waste management practice.

Benefits:

- No specialized equipment is required.

- Soil heating can be reduced.

- Top-lighting creates a more efficient burn resulting in less smoke.

- The process sequesters carbon as biochar, rather than releasing it as carbon dioxide.

- The method provides an opportunity to engage conservation groups or the local community in forest restoration activities (if they are constructing piles).

- Biochar can be locally used and provides soil and carbon storage benefits.

Challenges:

- Hand-piled biochar production takes longer than kiln-based or mobile biochar production methods.

- Biochar quality can be variable (depending on quality of the wood, moisture conditions, burn temperature, etc.).

- Quenching the coals requires water, and raking requires practitioner effort.

- Hand-piling requires contractors and staff to learn a new practice.

In conclusion, while traditional slash pile burning presents environmental drawbacks, hand-built piles offer a promising alternative for woody biomass disposal. Not only does biochar production minimize soil damage and smoke emissions, but it also creates a valuable soil amendment that can enhance water retention, promote healthier soil, and store carbon. While challenges like production time and variable biochar quality exist, the ease of construction, minimal equipment requirements, and potential community involvement make hand-built piles a compelling option for land managers seeking sustainable solutions for woody biomass management.

This webpage is a collaboration between the USDA Northwest Climate Hub and the USDA Forest Service Rocky Mountain Research Station.